Fluidized Bed Jet Mill

Features of Fluidized Bed Jet Mill LHL:

1. LHL series fluidized bed jet mills are not only suitable for superfine comminution of low-melting-point and thermosensitive materials, but also suitable for sugar-contained and volatile substances.

2. Finished products with a size from 3 to 180um could all be obtained.

3. Fluidized bed jet mills with a production capacity from 5 to 3,000kg/h are all available.

| Model Data | LHL-3 | LHL-6 | LHL-10 | LHL-20 | LHL-40 | LHL-60 | LHL-120 |

| Feed size (Mesh) | ≤ 20 | ≤ 20 | ≤ 20 | ≤ 20 | ≤ 20 | ≤ 20 | ≤ 20 |

| Fineness(d97=um) | 2-150 | 2-150 | 2-150 | 2-150 | 2-150 | 2-150 | 2-150 |

| Capacity (kg/h) | 15~100 | 40~250 | 90~500 | 200~1100 | 500~2500 | 750~4000 | 1500~8000 |

| Air consumption(m3/min) | 3 | 6 | 10 | 20 | 40 | 60 | 120 |

| Air pressure(MPa) | ≥0.8 | ≥0.8 | ≥0.8 | ≥0.8 | ≥0.8 | ≥0.8 | ≥0.8 |

| Installed power (kw) | 27.5 | 53 | 75 | 159 | 300 | 440 | 830 |

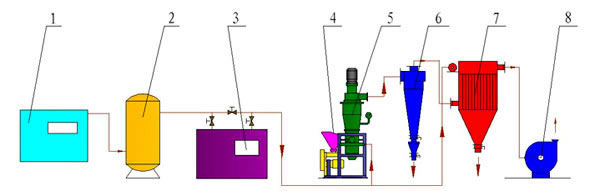

Flow Chart I

- 1. Air compressor

- 2. Air storage tank

- 3. Freeze drying machine

- 4. Feeding System

- 5. Main machine of jet grinding mill

- 6. Cyclonic collector

- 7. Pulsed dust collector

- 8. Induced draft fan

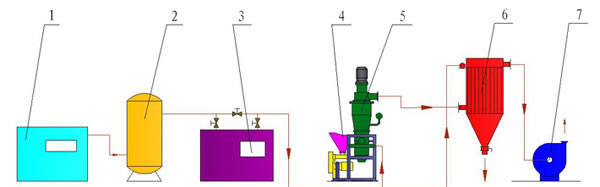

Flow Chart II

- 1. Air compressor

- 2. Air storage tank

- 3. Freeze drying machine

- 4. Feeding System

- 5. Main machine of jet mill

- 6. Pulsed dust collector

- 7. Induced draft fan

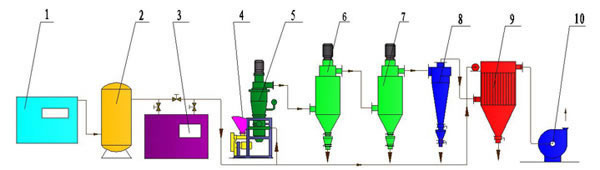

Flow Chart III

- 1. Air compressor

- 2. Air storage tank

- 3. Freeze drying machine

- 4. Feeding System

- 5. Main machine of grinding mill

- 6. Classifier I

- 7. Classifier II

- 8. Cyclonic collector

- 9. Bag filter

- 10. Induced draft fan

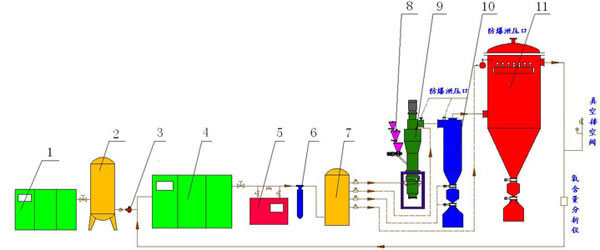

Explosive Prevention Flow Chart

- 1. Nitrogen generator

- 2. Air storage tank

- 3. Electromagnetic valve (contains directional valve)

- 4. Nitrogen compressor

- 5. Freeze drying machine

- 6. Deoiler

- 7. Pressure distributor

- 8. Closed type feeding system

- 9. Jet mill and classifier

- 10. Cyclonic collector

- 11. Bag filter

Weifang Zhengyuan Powder Engineering Equipment Co.,Ltd.

Add: No. 14177 Minzhuxi Street, Economic Development Zone, Weifang, Shandong

Tel: +86-536-2105390

Email: wfzy1998@gmail.com

wfzy1998@126.com

WhatsApp:

+86-13465660184

Inquiry Form